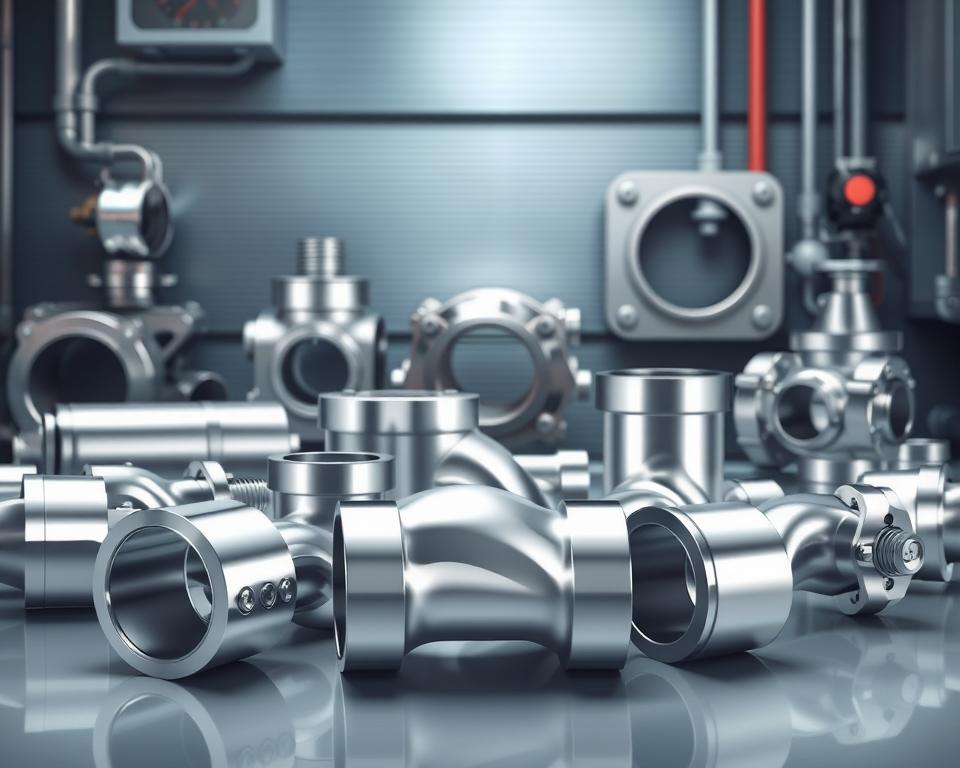

High-End Tri-Clamp Sanitary Fittings for Ultra-Clean Operations

In settings where cleanliness saves lives, even micro-fissures make a difference. Consequently, companies like Installation Parts Supply focus on expertly engineered solutions minimizing contamination. These hygienic connection systems unite robustness with effortless setup, making them a top choice for workplaces that require zero compromise.

These parts aren’t just about stopping drips – they’re designed to exceed the exacting standards of food processing, drink manufacturing, and biopharma plants. Forged from corrosion-resistant materials, they survive frequent cleaning cycles while preserving strength. The build mindset reflects industry leaders like Alfa Laval, prioritizing sanitary fitting smooth surfaces and rapid breakdown.

What sets these products apart? Think single-handed setup and tool-less upkeep. Workers value the logical interface during fast-paced operations, while plant managers cherish consistency across pipelines. Every piece faces rigorous inspections to guarantee adherence to FDA and 3-A Sanitary Standards.

Important Discoveries

- Adopted by industry pros for airtight reliability in hygiene-critical areas

- Fabricated in high-spec stainless steel for enduring toughness

- Simplifies compliance with food safety and pharmaceutical standards

- Shrinks production pauses through no-tool fitting and cleaning

- Supported through inspection regimes meeting global benchmarks

Product Overview and Key Benefits

Dependable joints are the backbone of hygienic processes. Installation Parts Supply creates components that combine high-precision build with operational practicality. Their offerings ensure hermetic sealing while making upkeep easy—critical for domains where rapid throughput meets sterility.

Premium Build & Sanitary Ratings

Every unit is put through robust checks to comply with worldwide norms. The substrates oppose oxidization, even after constant cleaning rounds. Hermetic joints prevent bacterial growth, a feature celebrated by dairy processors and pharmaceutical manufacturers alike.

These units parallel the standards of leaders like Alfa Laval, delivering smooth surfaces and uniform dimensions. Modular formats slot into running systems, trimming adaptation budgets. Technicians see 30% faster fitment compared to traditional threaded systems.

Competitive Advantages from Installation Parts Supply

Custom fabrication separates IPS from competitors. Demand a tricky angle or custom sheen? Their team co-designs with users to craft bespoke answers. Rapid fulfillment and 24/7 technical support keep production lines moving.

The benefits reach beyond lifespan. Snap-apart removal reduces lag during microbial reviews. Brew houses using these connectors report fewer production stoppages and uniform pressure. It’s not just about satisfying codes—it’s about surpassing them with ease.

Design Highlights & Technical Notes

Tight-tolerance build joins flexibility in current manufacturing networks. Installation Parts Supply fabricates components that unite exact measurements with versatile designs. Their strategy delivers smooth fitment into existing setups while preserving stringent sterility standards.

Selectable Materials & Polishings

Each application demands something different. That’s why alloy selections include 304 and 316L, chosen due to strength and corrosion resistance. Surface treatments like electro-finishing produce mirror-like smoothness, cutting microbial stickiness by up to 40% compared to standard finishes.

| Finish Type | Key Feature | Compliance |

|---|---|---|

| Electropolished | Ultra-smooth surface | ASME 3A, ISO 9001 |

| Mechanically Polished | Cost-effective shine | 3-A Sanitary Standards |

| Bead-Blasted | Non-reflective texture | FDA Food Code |

Manufacturing processes utilize optical scanners to ensure uniform wall thickness. Narrow allowances (±0.005″) eliminate thin zones in high-pressure environments. During quality checks, components receive X-ray scans and pressure tests to uncover microscopic flaws.

Personalization surpasses looks. Clients seek particular elbows, flange sizes, or dedicated coatings for chemical resistance. These bespoke solutions help industries meet evolving safety regulations without re-engineering full setups.

Application & Install Guide for Tri-Clamp Sanitary Connectors

Current quick-turn operations demand components that install quickly yet perform reliably. These fitting packages perform best in environments where rapidity intersects sterility. Their design scraps complicated hardware, allowing teams to focus on productivity rather than mounting issues.

Streamlined Setup Procedure

Coupled flange rims and a centered gasket generate fail-safe closures in seconds. Operators position the parts, insert the locking ring, and lock by grip – no wrenches required. This procedure reduces installation errors while holding steady load across the joint.

| Step | Traditional Method | Modern Solution |

|---|---|---|

| Alignment | Thread matching required | Flanged ends self-center |

| Sealing | Multiple tape layers | Single food-grade gasket |

| Securing | Torque wrench needed | Hand-tightened mechanism |

Convertible Connections for Gear

From stainless steel tubes to processing equipment, these interfaces unite different pieces smoothly. The uniform design mates to various diameters, facilitating rapid rearrangement during product changeovers. Dairy plants often use them to switch between cleaning cycles and production runs seamlessly.

Cleaning squads favor how components split for thorough sanitation. Smooth surfaces stop gunk accrual, while the thread-free design stops microbe pockets. Weekly cleanings need half the hours compared to older connection methods.

Field Deployments and Rule Conformity

Spanning artisan beer halls to inoculation plants, modern facilities use hardware that meet multiple objectives while meeting exacting rules. Installation Parts Supply brings solutions trusted across high-stakes domains where product purity is essential. Their designs bridge operational efficiency with regulatory demands, creating systems that perform under pressure.

Food, Beverage, and Pharmaceutical Sectors

Throughout refreshment operations, rapid-swap fittings streamline hopping from batch to CIP. Breweries rely on custom tees to manage complex flow paths minus impurity threats. Pharmaceutical manufacturers depend on airtight seals to defend reactive substances during sterile transfers.

These fittings ship in assorted gauges to match piping layouts, from pilot plants to bulk reactors. Dairy processors value how standardized parts reduce downtime during equipment upgrades. Even slight variations in production processes are handled through modular designs.

Meeting ASME, ISO & 3A Rules

Every product meets or exceeds benchmarks set by global organizations. ASME-certified materials handle high temperatures in pasteurization systems, while ISO-compliant finishes deny biofilm. The 3-A symbol assures fitness for direct contact with consumables.

Tri-Clamp unions demonstrate the devotion. Their uniform dimensions provide drip-free service across automated lines. Third-party audits confirm provenance from raw materials to finished goods, giving quality teams peace of mind.

By staying within these codes, facilities streamline certification processes and earn approvals quickly. It’s not just about avoiding fines—it’s about winning user assurance through clear proof of hygiene.

Summary & Suggested Actions

Deciding on solutions that unite throughput and regulation guides plant achievements. Installation Parts Supply offers systems marrying longevity and hygiene, granting leak-free performance across food, pharma, and beverage environments. Their products surpass rigorous standards while streamlining routine tasks through intuitive assembly.

With alternatives of grades and sheens, solutions fit special process specs. Whether carrying thermal streams or recurring sterilizations, material choices and surface treatments optimize longevity. Professionals enjoy the broad range of couplings made for particular throughput and pressure.

Placing orders is hassle-free, with specialist help on hand to suit project goals. Same-day shipping and responsive service minimize downtime during upgrades or replacements. Standard sanitation becomes effortless thanks to no-tool breakdown and slick interiors that fight fouling.

Eager to upgrade production assurance? Consult Installation Parts Supply to examine purpose-built arrangements – from hygienic clamp to Clover-type fittings – validated through superior inspection. Their team confirms present-day adherence while future-proofing operations.