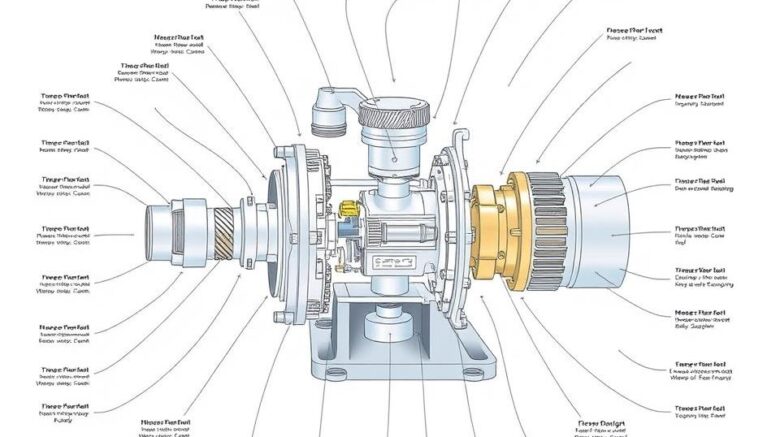

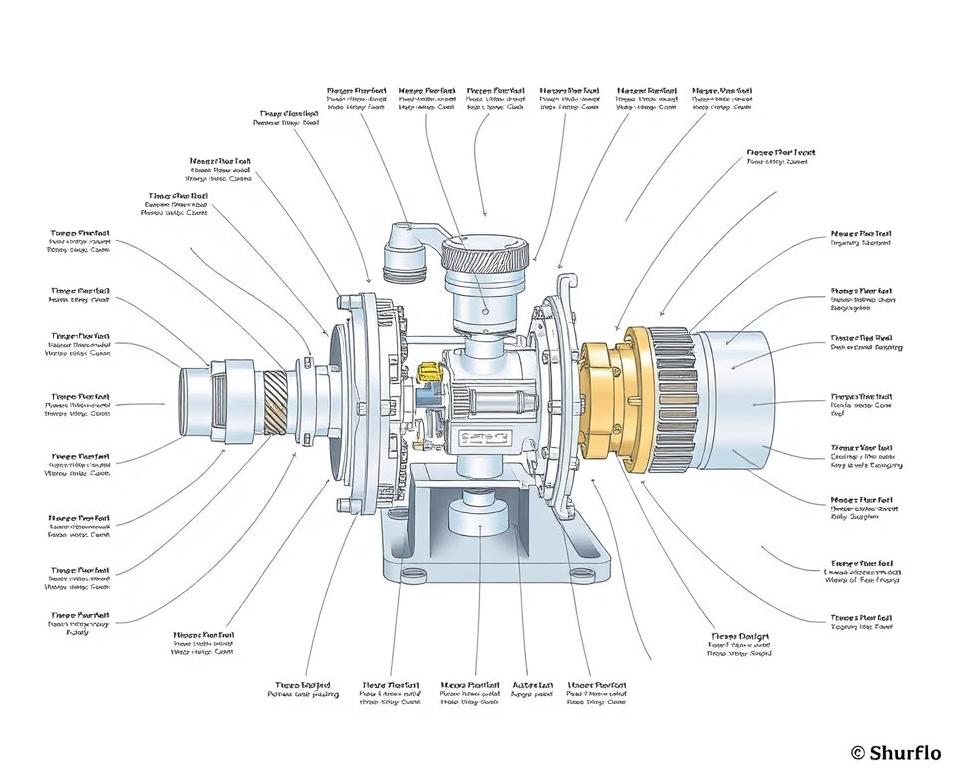

Shurflo Fluid Pump Diagram – Installation Components Supply

Incorrect installation of liquid pumping devices can dramatically reduce their effectiveness by up to 30%. It’s essential to comprehend the workings of the Shurflo Water Pump diagram for optimal operation and robustness. Each element within the diagram fulfills a key function in the Pump operation. This article examines the importance of understanding these Shurflo pumps parts catalog, using the diagram to illustrate their configuration and how they operate in unison.

Installation Parts Supply is your preferred provider for every Shurflo Water Pump element essential for assembly and servicing. Utilizing the Shurflo Pump parts schematic empowers users to proficiently manage installation and maintenance. This knowledge aids in making wise selections for the optimal and reliable performance of their Water Pump units.

Comprehending Shurflo Water Pumps

Shurflo Pump systems are at the intersection of ingenuity and practicality, meeting the demands of diverse applications. This segment strives to offer a comprehensive view of Shurflo Pump models, their specific uses, and the merits of selecting these pumps. They are famed for their state-of-the-art design and performance.

Summary of Shurflo Pump Types

Shurflo’s assortment comprises Pump models like the diaphragm and horticultural series, crafted for varied demands. The membrane models are celebrated for their robust build and ability to transfer fluids. Examples such as the 2088-343-135 and 2088-343-500 offer robust performance with notable flow and pressure ratings.

The agricultural series, conversely, is designed for optimal fluid conveyance in agricultural settings.

Applications of Shurflo Pump Systems

The adaptability of Shurflo Pump systems allows their use in a diversity of settings. They are commonly used for:

- Cultivation: Delivers options for watering and nutrient application.

- Recreational Vehicles: Guarantees uninterrupted Water Pump service with regulated pressure settings.

- Residential: Perfect for garden maintenance and residential water systems.

This versatility allows these devices to integrate smoothly into different systems, showing their adaptable nature.

Benefits of Employing Shurflo Pump Systems

Choosing Shurflo Pump systems provides several perks. Their automatic priming function erases the inconvenience of manual priming. They also possess corrosion resistance, making them durable under tough conditions. Readily available Shurflo diaphragm Water Pump parts facilitates maintenance, extending operational longevity while minimizing downtime. Further advantages of Shurflo Pump systems comprise:

- Steady output adjustable to various pressures.

- Easy installation supported by the Shurflo pumps parts catalog.

- Various connection options for smooth system integration.

With these attributes, Shurflo Pumps deliver efficiency and reliability. They maintain uninterrupted operation, assuring users of reliable operation.

Shurflo Water Pump Diagram and Its Importance

The Shurflo Pump schematic is essential for grasping its parts and workings. By studying the Shurflo Water Pump schematic, users can assemble, troubleshoot, and uphold effectiveness. This diagram is indispensable for determining the required Shurflo Pump parts. Correct configuration ensured through the diagram ensures optimal operation.

Primary Parts in the Schematic

The Shurflo Pump schematic displays critical parts required for effective function:

- Engine: The engine, the heart of the Pump, propels the impeller, enabling flows from 41 to 168 GPM.

- Membrane: Supports uniform flow and pressure.

- Check Valves: Crucial for preventing backflow, these valves guarantee that liquid is directed properly.

- Housing: With a maximum pressure of 200 PSI, the housing secures longevity.

Interpreting the Shurflo Pump Schematic

To analyze the Shurflo Water Pump diagram, one must pay attention to distinct symbols and markings:

- Learn the arrangement of components depicted in the diagram.

- Recognize the indicated flow path via directional arrows.

- Review annotations for specifics such as cable gauges and installation choices.

Familiarity with this diagram is essential for efficient construction, servicing, and determining required elements.

Setting Up Shurflo Water Pumps

Fitting a Shurflo Water Pump can improve the operation of any water setup. Knowing the necessary steps and components is vital for a good installation. This tutorial details essential procedures and necessary equipment for a successful setup.

Installation Procedure for a Shurflo Pump

- First, assemble all equipment for shurflo pump installation. Make sure you have items like an appropriate screwdriver, a wrench, and a 50-mesh strainer.

- Attach the 50-mesh strainer to the inlet of the Pump. Preferably, use a flexible hose for inlet connections to reduce fitting stress.

- Utilize a 1/2” to 3/8” barb splicer to fasten tubing attachments. To prevent leakage, choose reinforced tubing with Oetiker clamps.

- The pump should be wired to a properly grounded outlet. A licensed electrician must perform this to adhere to local codes.

- Pressurize the accumulator tank to 50 PSI with filtered air or nitrogen. This is vital for achieving ideal pressure levels.

- Mount a SHURflo 65 psi pressure reducer at the Pump’s inlet to maintain appropriate pressure conditions.

- Finalize the configuration by joining every element. Avoid overloading the motor’s amperage; incorporate thermal breakers for additional safety.

- Run a diagnostic test and confirm the pressure switch works as intended.

Necessary Equipment and Components for Setup

| Item | Information |

|---|---|

| 50-mesh strainer | Filters debris at the pump’s inlet to ensure optimal performance. |

| Pliable hose | Ideal for connecting the inlet, lessening stress on attachments. |

| Tubing splicer | 1/2” to 3/8” connection for secure tubing attachment. |

| Pressure tank | Pre-charged to 50 PSI for maintaining pressure. |

| Pressure switch | Regulates operation by monitoring pressure conditions. |

| Electrical equipment | Required for safe connections, ensure compliance with local electrical codes. |

| SHURflo 65 psi valve | Lowers incoming water pressure to stabilize Pump function. |

Diagnosing Frequent Problems in Shurflo Pumps

Learning to fix common issues with shurflo pumps improves their functionality. This section delivers a troubleshooting guide. It assists in identifying and remedying common issues to ensure smooth operation of the pumps. Problems related to operation, flow, and acoustics are addressed with effective fixes.

Typical Issues and Remedies

Various conditions may result in malfunctions with Shurflo Pumps. Below are key problems and their solutions:

- Pump operates without liquid movement: Examine the freshwater reservoir, review the water line for obstructions or faults, confirm correct priming, and validate Pump operation.

- Pump won’t turn on after winterization: Examine winterization methods, ascertain all valves are operable, inspect electrical setups, and search for signs of damage.

- Pump cycling on and off: Examine the system for leakages, purge air pockets, set correct pressure levels, and confirm Pump operation.

- Pump producing excessive noise: Check for unsecured fittings, incorporate vibration dampening, insulate piping, and verify correct mounting.

Shurflo Pump Diagnostic Manual

A complete Shurflo Pump troubleshooting guide aids in swift diagnosis. The following table summarizes typical issues and corrective actions:

| Frequent Problem | Possible Reasons | Remedies |

|---|---|---|

| Operation without liquid movement | Low freshwater tank, blockages, improper priming | Check tank level, inspect water line, verify pump function |

| Failure to start | Incorrect winter procedures, blocked valves, wiring faults | Review winterization, open valves, check connections |

| Intermittent cycling | Leaks, air in system, pressure issues | Examine for leakages, eliminate air, modify pressure controls |

| Noisy pump | Loose connections, inadequate installation | Tighten connections, add padding, insulate pipes |

Comprehending the shurflo pump exploded view aids in identifying the parts causing problems is key to proper troubleshooting. Adhering to these guidelines ensures pump maintenance and reliable operation.

Final Thoughts

Understanding the Shurflo Water Pump schematic is vital for achieving maximum Pump efficiency.

Utilized in various fields like RVs and agricultural spraying, efficient setup is crucial for dependable outcomes.

Knowledge of the schematic’s components enables proficient assembly and upkeep of systems.

Installation Parts Supply is paramount for obtaining all needed Shurflo pump parts and services, providing complete assistance with access to crucial equipment and parts. Such support guarantees proper assembly. By adhering to proper plumbing, wiring, and upkeep of parts like the strainer, the operational life and efficiency of the Pumps are boosted.

This write-up provides the insights needed to enhance overall Shurflo system operation. Employing Shurflo Pump technology alongside these installation recommendations readies users to overcome any obstacles confidently.